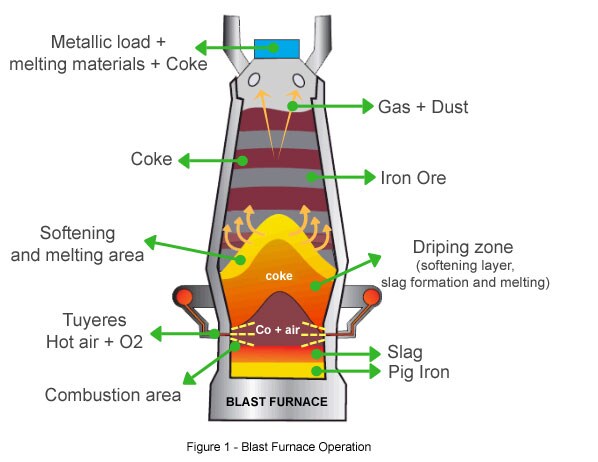

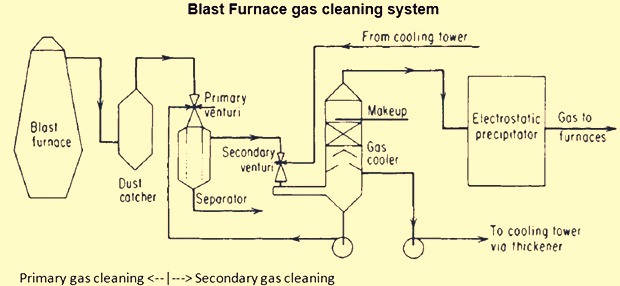

To generate the necessary heat and the reducing carbon monoxide gas co the coke is burnt in the lower part of the blast furnace with the supply of the hot blast.

Blast furnace parts and functions.

Fuel is also used at double the rate of regular furnaces so the number of items smelted per fuel stays the same.

The furnace here only requires half as much coal when smelting usually so it can be useful when smelting the ores that require more coal.

The furnace here only requires half as much coal when smelting usually so it can be useful when smelting the ores that require more coal.

The carbon c contained in the coke initially reacts with the.

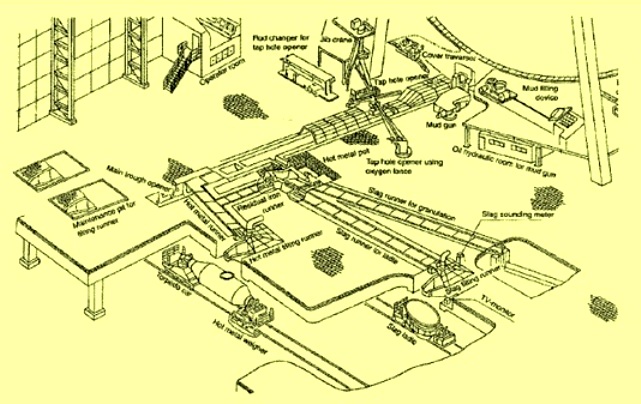

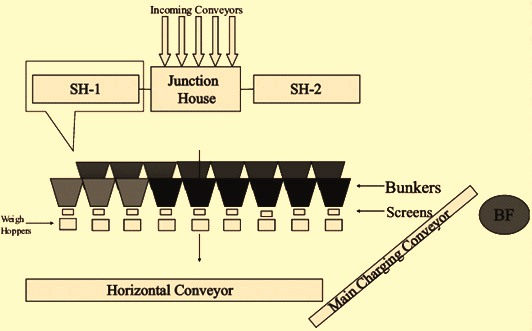

The burden charge consisting of iron oxide flux and coke and it provides through the throat from the top of the furnace.

The individual chemical processes in the blast furnace are described in more detail in the following sections.

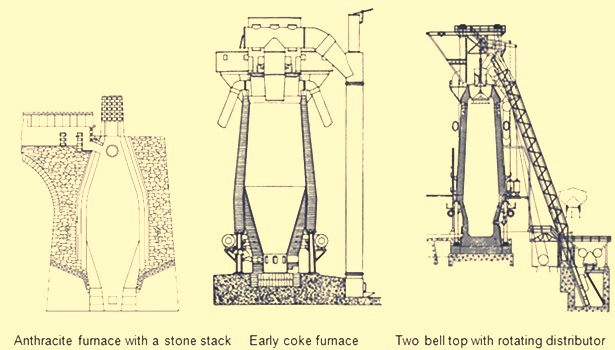

Blast furnaces are used to produce pig iron from iron ore for subsequent processing into steel and they are also employed in processing lead copper and other metals.

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals generally pig iron but also others such as lead or copper.

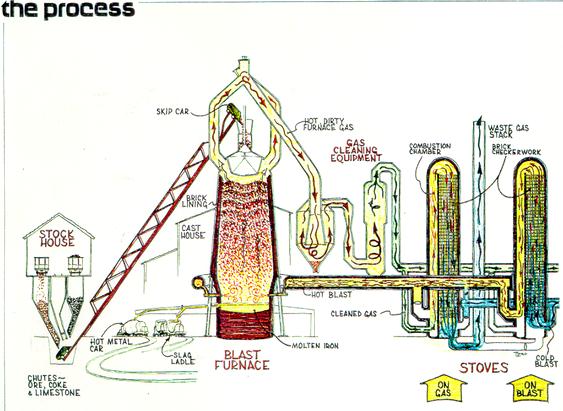

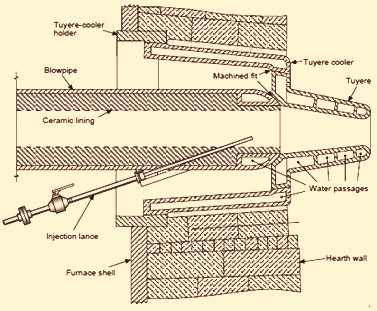

An air blower is connected to the wind box by means of blast pipe.

Smelting equipment yields one iron or gold nugget from their respective materials.

It supplies the air to the wind box.

Essentially the stove is a vertical cylindrical steel shell lined with firebrick and with the interior separated into two chambers.

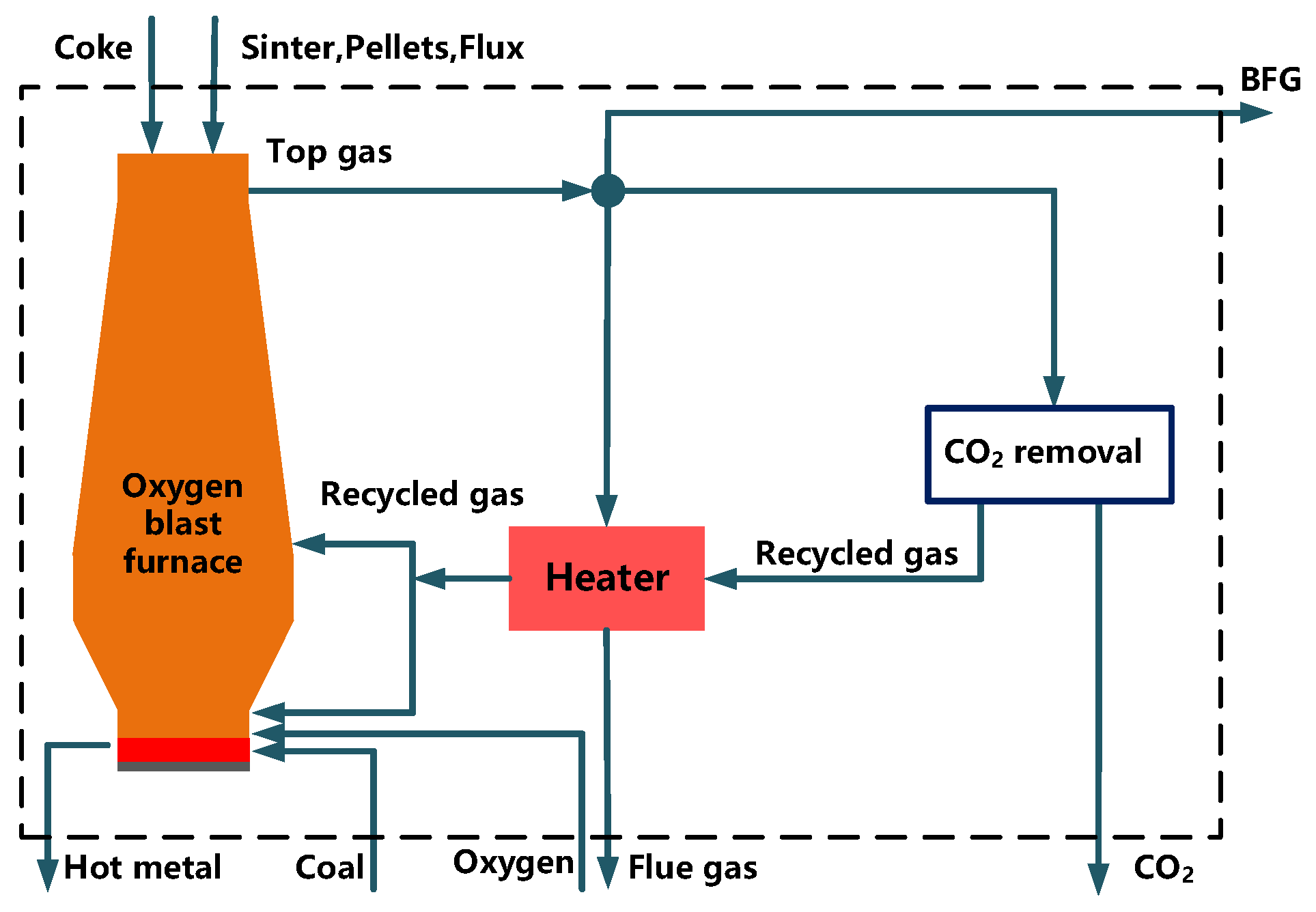

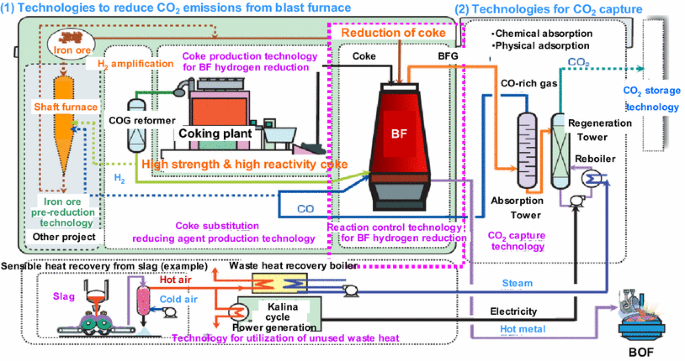

Co 2 capture from the overall flue gas stream.

Blast refers to the combustion air being forced or supplied above atmospheric pressure.

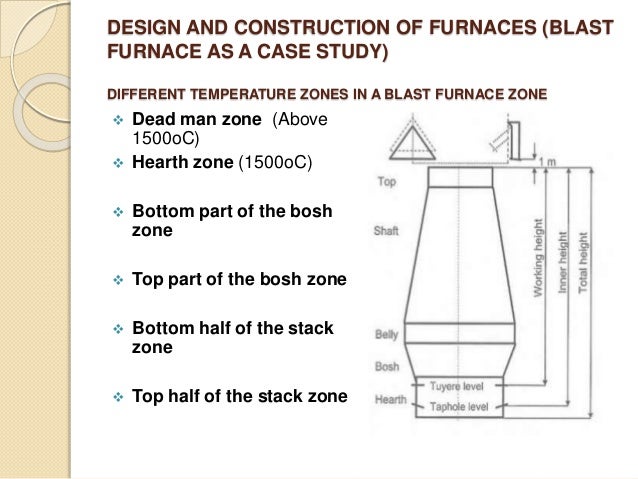

Blast furnace and process description iron blast furnace is a vertical shaft which is used to melt the iron ore and to produce hot metal by heat exchange and chemical reaction.

The blast furnace is a members only minigame situated in keldagrim for smelting bars.

The blast furnace worlds on old school runescape are worlds 352 355 358 386 and 387.

A combustion chamber in which gases from the blast furnace and from other fuel sources such as the coking plant are burned and a regenerative chamber filled with a checkerwork of refractory brick heated by the burned gas.

A valve is provided in the blast pipe to control the flow of air.

In a blast furnace fuel ores and flux are continuously supplied through the top of the furnace while a hot blast of air is blown into the lower section of the furnace through a series of pipes called tuyeres so that the chemical reactions take pl.

The blast furnace is a members only minigame situated in keldagrim for smelting bars which require coal.

Blast furnace gases contain close to 30 co 2 after full combustion of the co fraction while the overall flue gas stream from an integrated steel mill is 15 co 2 the same co 2 capture options introduced above for power generation plant can therefore also be applied to a steel mill.

The blast pressure varies from 250 kg m 2 to 1050 kg m 2.

Firing the blast furnace with oxygen rather than air.

Blast furnaces also serve as the counterpart to smokers which are used mainly to cook food faster.